HAF-100-BF is special designing for rotation molding products PU filling process,

we success exported to many countrys, for cooller PU filling process,

The main technical characteristics of the equipment are as follows:

★ The foaming machine is compatible with F11, 141B, 245fa and full water foaming systems;

★ The POLY and ISO material pressure needle valve is locked after balance to ensure that

there is no pressure difference between POLY and ISO material;

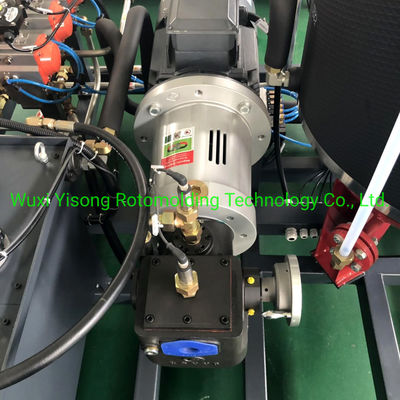

★ Magnetic coupling adopts high-tech permanent magnetic control, no temperature rise,

no leakage.

★ Automatic timing clean the mixing head after injection;

★ 16 work stations production can be adopted, which can satisfy the production of multiple

products. Mixing head using double (more) proximity switch control can achieve accurate

injection;

★ Frequency converter soft start and high and low frequency automatic switching, low

Carbon energy saving and environmental protection, energy consumption greatly

reduced;

★ Full digital, modular integrated control of all processes, accurate, safe, intuitive,

intelligent, humanized;

★ The synchronous measuring material ratio of the mixing head feed line is more accurate

Than that of the system loop measuring and the single component measuring of the

mixing head;

★The complete closed-loop pouring of the equipment, automatic identification and

Adjustment of the filling material at each station, feeding material, robot pouring,

automatic control and rolling bubble are completed in one process.

Main Technical Parameters of HAF100-BF High Pressure PU Foaming machine

| NO. |

Project |

Technical Parameters

|

| 1 |

Applicable foam type |

Rigid Foam |

| 2 |

Applicable raw material

viscosity(22ºC) |

POLY : 2500MPas

ISO : 1000MPas |

| 3 |

Injection pressure |

10~20Mpa(Adjustable) |

| 4 |

Injection flow(Mix ratio 1:1) |

150g~1500g/s |

| 5 |

Mixing ratio range |

POLY1 : ISO1 = 1:5 ~ 5:1 (Adjustable) |

| 6 |

Injection time setting |

0.1~99.99s (Accurate to 1s) |

| 7 |

Material temperature control error |

±2ºC |

| 8 |

Inject procedure recipe |

16 pcs |

| 9 |

Reinjection accuracy |

±1% |

| 10 |

Mixing head |

YZL1218-2k 1set |

| 11 |

Hydraulic system |

Flow ~10L/min

system pressure 10~25MPa |

| 12 |

Tank volume |

260L |

| 13 |

High voltage setup time |

0.7s |

| 14 |

Interval time of injection |

≥0.7s |

| 15 |

Compressed air requirement

|

Dry and oil-free P:0.7Mpa

Q:600NL/min |

| 16 |

Nitrogen requirement

|

P:0.7Mpa

Q:600NL/min |

| 17 |

Temperature control system |

Heating power of chiller and water heater: 2 x 2KW

Cooling: 15000Kcal/h (refrigeration capacity) |

| 18 |

Input power |

Three-phase five-wire, 380V, error 10%,power: 38KW |

19

|

Machine size(mm)

(length×width×height) |

3900×1400×2900 |

| 20 |

Design of inject Method |

manual injection foaming |

this is very stable machine, all the cable and tube are be marked with reference number

our customer can buy this machine and install independing very easier,

If you are planing to purchas one PU foaming machine for your rotomolding product,

we are with confidence to recommand you consinder this machine

Our experience told us, This machine is really less problem and trustable quality,

Please contact us for the machine offer .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!