Product Description:

Rotomoulding Mould is a highly customized solution for rotational moulding, CNC machining and other applications. It offers customizable features, such as size, weight and surface. The moulds are precisely machined with smooth surface finish to ensure high-quality products. The moulds are lightweight and can be used for a variety of rotational moulding processes. They are ideal for creating intricate shapes and details in products like toys, furniture, containers and other plastic products. The moulds are designed to provide superior strength and durability, while providing excellent product consistency and quality.

Rotomoulding Mould is an ideal solution for those seeking efficient and cost-effective moulding solutions. It provides the right balance between quality and cost, making it a great choice for a variety of applications. The moulds are designed to last for a long time, with minimal maintenance and upkeep required. They are also easy to use and maintain, allowing for a quick and easy setup process. With its superior strength and durability, Rotomoulding Mould is an ideal choice for rotational moulding and other applications.

Applications:

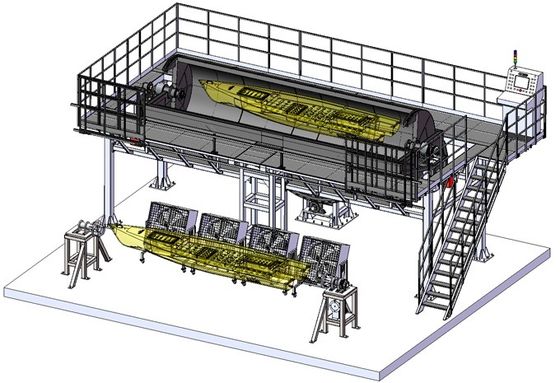

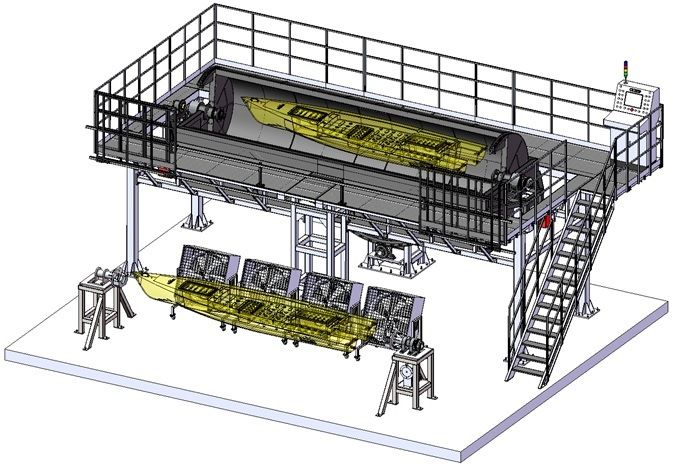

Rotomoulding Mould refers to a process of manufacturing by using a Rotational Molding technique to create hollow plastic components. This technique is mainly used for large, complex-shaped plastic parts. It is best suited for products such as water tanks, fuel tanks, agricultural tanks, and many other customized products. The process involves the use of a mold made from Aluminum Alloy with a Thickness of 3mm. The mold is usually heated to a certain temperature and then filled with the desired material. After cooling, the mold is then removed, and a hollow, plastic part is produced. The size of the product can be Customized according to the customer's needs. The walls of the product typically have a Wall Thickness of 8-10mm. The finished product is then packaged in a Wooden Case for safe transportation and storage.

Customization:

Customized Rotomoulding Mold

- Warranty: 1 Year

- Size: Customized

- Design: Customized

- Wall Thickness: 8-10mm

- Shape: Vertical / Horizontal

Our rotational molding, also known as rotomoulding, is a versatile and economical method for customizing your rotomoulding mold. Our high-quality molds come with a 1 year warranty, and can be customized in size, design, wall thickness, and shape (vertical/horizontal).

Support and Services:

Rotomoulding Mould Technical Support and Service

We provide technical support and services for Rotomoulding Moulds, to help you get the most out of your moulds and ensure they perform as expected.

Our experienced team of engineers and technicians are on-hand to provide advice and guidance on the best way to use your moulds, and to answer any questions you might have.

We also provide maintenance services, such as cleaning and inspection, to help keep your moulds in good working order. We can also repair any issues that may arise with your moulds.

If you need further assistance, please don't hesitate to contact us. We look forward to helping you get the most out of your Rotomoulding Moulds.

Packing and Shipping:

Packaging and Shipping for Rotomoulding Mould:

The product should be packaged in a cardboard box with dimensions appropriate for the mould size. It should be protected with bubble wrap for added protection. The box should then be sealed securely with tape and clearly labelled with the address of the recipient.

The mould should then be shipped in a reliable courier service such as FedEx or DHL. It should be insured for the full value of the mould and tracked to ensure safe and timely delivery.

FAQ:

Q&A about Rotomoulding Mould

What is Rotomoulding Mould?

Rotomoulding Mould is a type of mould used in rotational moulding for producing hollow plastic parts.

What are the advantages of Rotomoulding Mould?

Rotomoulding Mould has many advantages, including high product uniformity, low cost, short production cycle, and no need for secondary processing.

What materials can be used for Rotomoulding Mould?

Rotomoulding Mould can be made of various materials including aluminum, steel, and stainless steel.

What kind of design is suitable for Rotomoulding Mould?

Rotomoulding Mould can be designed with various shapes, sizes, and functions to meet different needs.

What is the typical production cycle of Rotomoulding Mould?

The typical production cycle of Rotomoulding Mould is generally about 5 to 10 days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!