Product Description:

Rotomoulding Mold is an essential tool in rotational moulding process, which is widely used for producing various kinds of hollow plastic products. It is featured by high precision and accuracy, with tolerance up to ±0.1mm. The weight and size of the mold can be customized according to specific requirement. The mold is made through CNC machining technology, which ensures high accuracy and consistency of the product. With the help of our rotomoulding mold, you can make high quality products with ease. It is suitable for a wide range of applications, such as automotive industry, chemical industry, medical industry, and so on. Our rotomoulding mold is the best choice for creating rotational moulding products.

Features:

- Product Name: Rotomoulding Mould

- Tolerance: ±0.1mm

- Shape: Vertical / Horizontal

- Package: Wooden Case

- Color: Silver

- Material: Aluminum Alloy

Technical Parameters:

| Parameter |

Description |

| Warranty |

1 Year |

| Size |

Customized |

| Color |

Silver |

| Weight |

Customized |

| Surface |

Smooth |

| Processing |

CNC Machining |

| Wall Thickness |

8-10mm |

| Heat Treatment |

Annealing |

| Package |

Wooden Case |

| Material |

Aluminum Alloy |

Applications:

Rotomoulding Mould is a highly versatile and cost-effective tool for a variety of applications. It is ideal for creating consistent, reliable and durable shapes, and is made from a wooden case that is strong and durable. It has a vertical or horizontal shape, and its wall thickness is 8-10mm, making it suitable for a variety of uses. The rotomoulding mould is made using CNC machining technology, which ensures the highest quality and precision. The mold is also available in a range of colors, including silver. As such, it is a great option for many industries, ranging from automotive, to medical, to industrial, and more.

With rotomoulding mould, you can easily create a wide range of shapes and sizes, with consistent quality and reliability. The mould is easy to use and can be used in a variety of applications, from automotive, to medical, to industrial. Its wall thickness of 8-10mm makes it perfect for creating intricate shapes and details for a variety of products. Moreover, the wooden case makes it highly durable and long lasting.

Rotomoulding mould is the perfect choice for those looking for a reliable and cost-effective tool for their rotomoulding needs. It is easy to use and provides a consistent, reliable and durable shape for a variety of products. It is made from a wooden case, and its wall thickness of 8-10mm makes it ideal for creating intricate shapes and details. In addition, it is available in a range of colors, including silver, making it a great choice for many industries.

Customization:

Custom Rotomoulding Moulds

We provide custom Rotomoulding Moulds for Rotational Molding, tailored to your individual requirements. Our Rotomoulding Moulds come with customized weight and design, and a silver color finish. You can choose from a vertical or horizontal shape.

Our Rotomoulding Moulds are designed to your exact specifications, ensuring maximum quality and precision.

With years of experience in the industry, we are committed to providing the highest quality Rotomoulding Moulds to meet your needs.

Support and Services:

Rotomoulding Mould Technical Support and Service

Rotomoulding Mould offers a wide range of technical support and services for moulds. Our team of experienced and dedicated professionals provides a variety of services to meet your specific requirements and ensure that your moulds are produced correctly and efficiently.

Design Services

We offer design services to help create the perfect mould for your application. Our experienced engineers can help you create a mould that is suitable for your specific application. We will work with you to ensure the design fits your needs and is within your budget.

Manufacturing Services

Our manufacturing services include molding, machining, and fabrication. We use the latest technology and equipment to ensure that your moulds are produced with the utmost precision and quality. We can also provide custom solutions to meet your unique needs.

Technical Support

Our team of experienced technicians is available to provide technical support for your moulds. Our technicians can provide assistance with troubleshooting, repairs, and maintenance. We can also provide advice on the best materials and processes for your moulds.

Installation and Training

We offer installation and training services to ensure that your moulds are installed correctly and operate smoothly. Our technicians can help with the installation process and provide training on the proper use and maintenance of your moulds.

Packing and Shipping:

Packaging and Shipping of Rotomoulding Mould:

Rotomoulding moulds should be securely packaged and shipped with great care. The moulds should be wrapped in foam, bubble wrap, or other cushioning material to prevent any damage or scratches during transit. The packages should also be marked clearly with the customer’s name, address, and phone number.

The moulds should be placed in a sturdy, corrugated cardboard box that is large enough to contain the moulds and the cushioning material safely. The box should be taped securely with strong packing tape to prevent any movement or damage in transit. The boxes should also be clearly labeled with the customer’s name, address, and phone number.

Once packaged, the moulds should be shipped with a reliable and trusted shipping provider. The shipping provider should be chosen based on their track record of safe and secure delivery. The customer should be informed of the shipment and provided with tracking information when available.

FAQ:

- Q:What is a rotomoulding mould?

- A:Rotomoulding mould is a type of plastic moulding process, which is used to create hollow parts by rotating a heated hollow mould in two perpendicular axes.

- Q:What are the benefits of using rotomoulding mould?

- A:Rotomoulding moulds offer a number of benefits, such as cost savings, low-volume production capabilities, and the ability to create complex shapes.

- Q:What materials can be used with rotomoulding mould?

- A:Rotomoulding moulds can be used with a variety of materials, including polyethylene, polypropylene, PVC, and nylon.

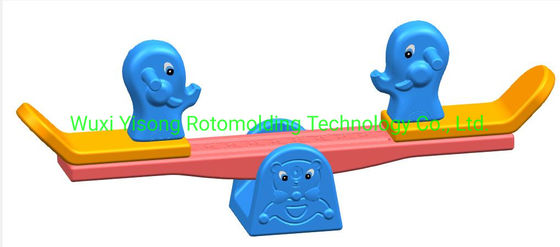

- Q:What types of products can be made with rotomoulding mould?

- A:Rotomoulding moulds can be used to create a wide variety of products, such as tanks, toys, furniture, and other hollow parts.

- Q:How long does the rotomoulding mould process take?

- A:The rotomoulding mould process typically takes between 10 to 15 minutes, depending on the size and complexity of the product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!