Silver Rotational Mold Molding With 8-10mm Wall Thickness For Various Applications

Product Description:

Rotomoulding Mold

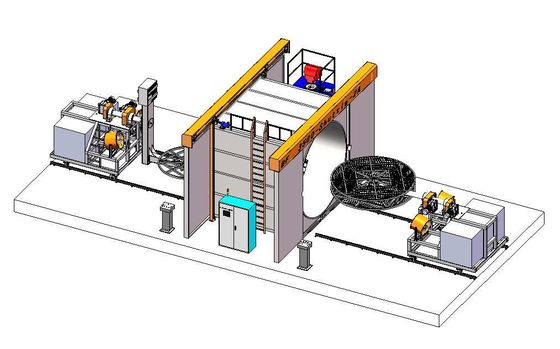

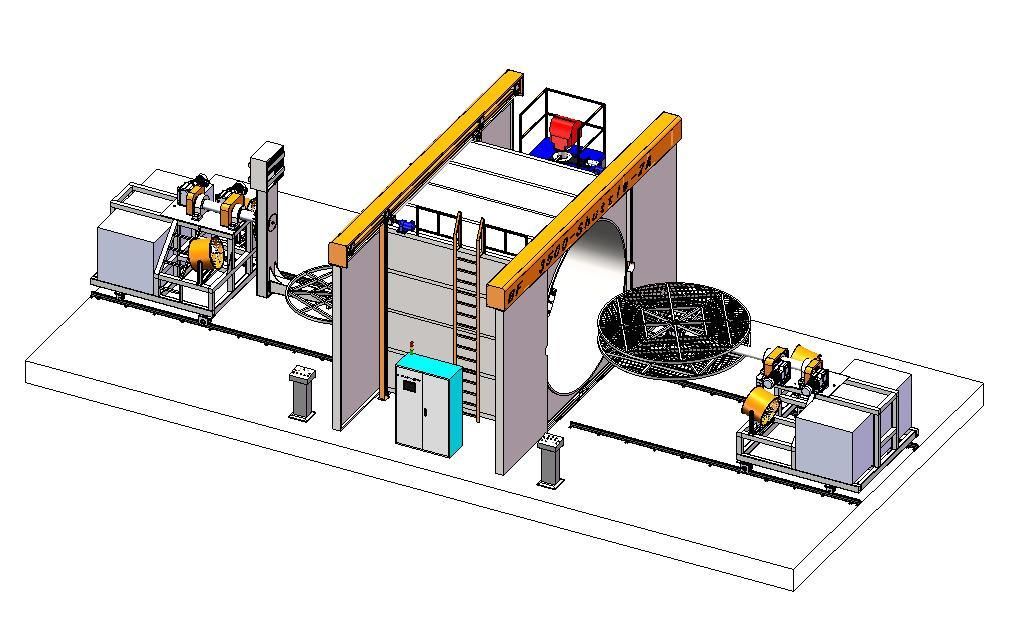

Rotomoulding is a process of producing hollow parts and products by using thermoplastic materials. It is one of the most popular manufacturing techniques in the plastic industry. Our rotomoulding mold is made of high-quality and durable aluminum alloy, which is suitable for producing hollow products in various shapes. The wall thickness of the mold can be customized to 8-10mm and the tolerance is ±0.1mm, so you can get the desired shape and size.

Our rotomoulding mold is widely used in rotational moulding process, which is suitable for producing plastic products with complex shapes. With advanced design and technology, our rotomoulding mold is reliable and precise, providing you with the perfect products. We have a professional team to serve you and guarantee the quality of our products.

Features:

- Product Name: Rotomoulding Mould

- Processing: CNC Machining

- Heat Treatment: Annealing

- Design: Customized

- Shape: Vertical / Horizontal

- Thickness: 3mm

- Specialty: Rotational Moulding Mold

Technical Parameters:

| Property |

Value |

| Weight |

Customized |

| Heat Treatment |

Annealing |

| Surface |

Smooth |

| Material |

Aluminum Alloy |

| Application |

Rotomoulding |

| Warranty |

1 Year |

| Color |

Silver |

| Size |

Customized |

| Wall Thickness |

8-10mm |

| Tolerance |

±0.1mm |

Applications:

Rotomoulding Mold is widely used in all kinds of applications and scenarios for its outstanding features including one year warranty, smooth surface, 8-10mm wall thickness, customized weight and design. With these features, Rotomoulding Mold is the ideal solution for a variety of challenging and complex projects. It is lightweight, yet strong and durable, making it suitable for a range of applications from industrial to commercial use. The custom design and weight provide a perfect fit for every application. The rotational moulding process and the high-quality material used in the production make Rotomoulding Mold extremely reliable and long-lasting.

Rotomoulding Mold is ideal for industrial projects, such as tanks or other containers, as well as for commercial projects, such as furniture or playground equipment. It is perfect for large-scale projects such as outdoor pools or large-scale structures. It is also highly suitable for any project that requires a customized design and weight. The rotational moulding process ensures a consistent and reliable quality product, and the one year warranty ensures that customers can rely on the product for a long period of time.

Rotomoulding Mold is the perfect solution for any project that requires a product with a long-lasting and reliable quality, and with a customized design and weight. With its one year warranty, smooth surface, 8-10mm wall thickness, and customized weight and design, Rotomoulding Mold is the ideal choice for any project. Whether it is for industrial or commercial use, Rotomoulding Mold provides a perfect solution for any challenging and complex project.

Customization:

Custom Rotomoulding Mould

- Heat Treatment: Annealing

- Design: Customized

- Tolerance: ±0.1mm

- Warranty: 1 Year

- Wall Thickness: 8-10mm

At Rotational_Mold_Molding, we specialize in Rotational_Molding_Mold and Rotomoulding_Mold_Molding. We offer custom Rotomoulding Moulds with a heat treatment of annealing, customized design, tolerance of ±0.1mm, 1 year warranty and wall thickness of 8-10mm.

Support and Services:

Rotomoulding Mould Technical Support and Services

We provide technical support and services for our Rotomoulding mould products. Our technical support team is always available to answer any questions you may have about your mould and offer advice on its use.

We also offer a range of services to ensure that your mould is in optimum condition and performs to its best. Our services include:

- Diagnosing and resolving any mould issues quickly and efficiently.

- Ensuring that the mould is running efficiently and safely.

- Providing advice and recommendations to improve the performance of the mould.

- Providing training on the use of the mould.

- Regular maintenance and servicing of the mould.

We are committed to providing the best technical support and services for our Rotomoulding mould products, so you can be sure that your mould is running safely and efficiently.

Packing and Shipping:

For packaging and shipping a Rotomoulding Mould, the following steps should be taken:

- The mould should be wrapped in a protective film and placed into a cardboard box.

- The box should be labeled with the mould's specifications and destination information.

- The box should be loaded onto a pallet and secured with straps or plastic wrap.

- The pallet should be placed in a freight container, and the container should be sealed for transport.

FAQ:

Q&A about Rotomoulding Mould

Q1: What is rotomoulding mould?

A1: Rotomoulding mould is a kind of mould used for manufacturing plastic products by rotational molding.

Q2: How is it different from other kinds of mould?

A2: Compared with other kinds of mould, rotomoulding mould has more advantages such as low cost, high efficiency, and uniform thickness.

Q3: What kind of materials can be used in rotomoulding mould?

A3: Commonly used materials for rotomoulding mould include polyethylene, polypropylene, nylon, and vinyl.

Q4: How long does it take to produce a rotomoulding mould?

A4: The production time of a rotomoulding mould varies greatly depending on the complexity of the product. Generally, it takes about 7 to 15 days.

Q5: What should be taken into account when using rotomoulding mould?

A5: To ensure the quality of the product, it is necessary to pay attention to the details of the product design, the quality of the raw materials used, and the temperature and pressure of the mould during production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!