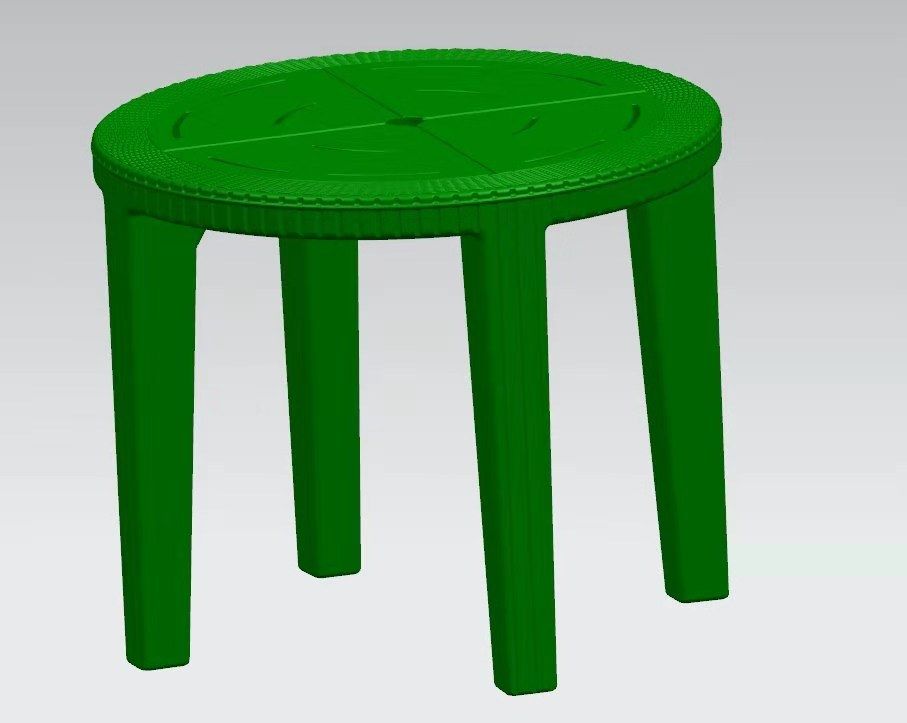

Versatile Rotational Moulding Mold - 3mm Thickness For Versatile Manufacturing

Product Description:

Rotomoulding Mould is a kind of rotational molding process that produces hollow parts with uniform wall thickness through CNC machining. It is widely used in the production of various tanks, containers, and covers of different shapes. The main feature of this product is that it can be customized in color, weight, and shape, ranging from vertical to horizontal with wall thickness of 8-10mm. It is the perfect choice for those who need precise and high-quality products. Rotomoulding Mold is also known as Rotational Molding Mold or Rotational Moulding Mold, which offers an excellent combination of strength, durability, and versatility.

Features:

- Product Name: Rotomoulding Mould

- Material: Aluminum Alloy

- Design: Customized

- Thickness: 3mm

- Processing: CNC Machining

- Application: Rotomoulding

Technical Parameters:

| Parameter |

Value |

| Design |

Customized |

| Wall Thickness |

8-10mm |

| Weight |

Customized |

| Thickness |

3mm |

| Heat Treatment |

Annealing |

| Size |

Customized |

| Warranty |

1 Year |

| Application |

Rotomoulding |

| Surface |

Smooth |

| Shape |

Vertical / Horizontal |

Applications:

Rotomoulding Mould

Rotomoulding mould is an ideal solution for creating a wide range of various products with intricate shapes and smooth surfaces. It is a cost-effective manufacturing process that can be used to produce customized products of various sizes and weights. The rotomoulding process allows for a wide range of colors, including silver, and the finished product can be packaged in a wooden case for storage and transport.

The rotomoulding process is a highly versatile and efficient manufacturing method, and it is perfect for producing products with complex shapes and sizes. It is also a great option for creating products that require a smooth, even surface. The rotomoulding process can also be used to customize the weight of a product, as the moulding process allows for precise weight control.

Rotomoulding mould is a great choice for creating a range of products with a perfect finish. It is a cost-effective manufacturing method that can be used to produce customized products of various sizes and weights. It also provides the opportunity for customers to choose from a range of colors, including silver, and the product can be packaged in a wooden case for storage and transport.

Customization:

Customized Rotomoulding Mold

Are you looking for a reliable rotomoulding mold supplier to manufacture your custom-made product? Look no further! We provide customized rotomolding mold service that can meet your needs.

- Application: Rotomoulding

- Thickness: 3mm

- Tolerance: ±0.1mm

- Surface: Smooth

- Shape: Vertical / Horizontal

Our rotational molding molds are specially designed for rotational molding process, providing superior strength and durability. We have over 10 years of experience in customized rotational moulding molds and have earned a reputation for providing quality products.

Contact us today to discuss your customized rotomoulding mold needs!

Support and Services:

Rotomoulding Mould Technical Support and Services

At Rotomoulding Mould, we offer comprehensive technical support and services to ensure that our products are running smoothly. We have a team of experienced professionals who are knowledgeable in all aspects of our products and services.

Our technical support team is available during regular business hours and can be contacted by telephone, email, or live chat. They are knowledgeable in all aspects of Rotomoulding Mould and can provide troubleshooting, installation assistance, and product training. Our technical support team can also assist with product customization and integration.

Our services team can provide onsite maintenance and repairs, as well as remote diagnostics and troubleshooting. We also offer regular maintenance and inspection services to ensure that our products are functioning properly. If any issues arise, our services team is available to provide repairs and replacements.

At Rotomoulding Mould, we are dedicated to providing the highest level of customer service and technical support. Our experienced professionals are always available to answer any questions or concerns you may have.

Packing and Shipping:

Packaging and Shipping for Rotomoulding Mould:

- The moulds will be carefully packed in sturdy, corrugated boxes.

- The boxes will be sealed with tape and labeled with the product name.

- The moulds will be shipped using a reliable courier service.

- The shipment will be tracked and insured.

FAQ:

Q1: What is Rotomoulding Mould?

A1: Rotomoulding Mould is a type of mould used in the rotational moulding process to form hollow plastic products or components.

Q2: What materials are used for Rotomoulding Mould?

A2: Rotomoulding Moulds are typically made from aluminum, stainless steel, or steel alloys.

Q3: What is the lead time for Rotomoulding Mould?

A3: The lead time depends on the complexity of the mould design and the size of the mould. Generally, it takes about 4 to 6 weeks from design to delivery.

Q4: How long can a Rotomoulding Mould last?

A4: The life span of a Rotomoulding Mould depends on the quality of the material used, the complexity of the design and the frequency of use. Generally, a Rotomoulding Mould can last for up to 10 years.

Q5: Is it possible to make modifications to a Rotomoulding Mould?

A5: Yes, it is possible to make modifications to a Rotomoulding Mould. Depending on the complexity of the changes, it may require a new mould to be created.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!