Achieve 8-10mm Wall Thickness Rotational Mold Molding And Specialized CNC Machining

Product Description:

Rotomoulding Mold is a kind of rotational molding tool used in rotomoulding process. It is made with precision tolerances of ±0.1mm, ensuring the surface is smooth and uniform. Moreover, with annealing heat treatment, it can guarantee a long-term warranty of 1 year. This kind of rotational molding mold is mainly used for rotomoulding, and it is highly recommended for rotational moulding process.

Features:

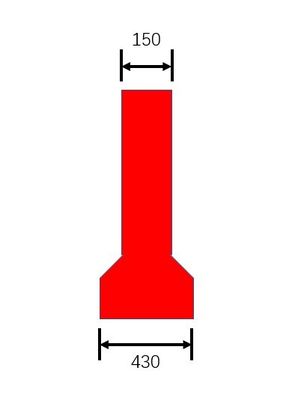

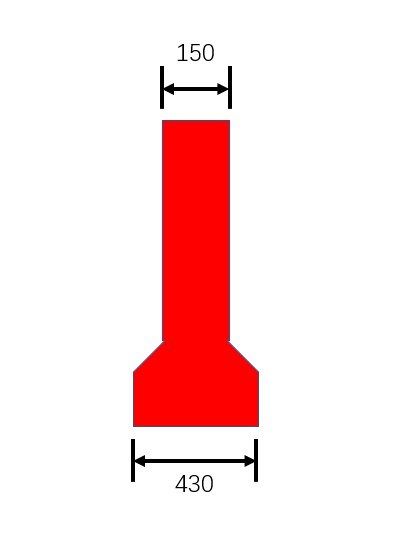

- Product Name: Rotomoulding Mould

- Wall Thickness: 8-10mm

- Application: Rotomoulding

- Size: Customized

- Surface: Smooth

- Thickness: 3mm

- Rotational Moulding Mold

- Rotomoulding Mold Molding

- Rotational Mold Molding

Technical Parameters:

| Parameter |

Value |

| Weight |

Customized |

| Color |

Silver |

| Package |

Wooden Case |

| Design |

Customized |

| Size |

Customized |

| Tolerance |

±0.1mm |

| Shape |

Vertical / Horizontal |

| Wall Thickness |

8-10mm |

| Surface |

Smooth |

| Warranty |

1 Year |

Applications:

Rotomoulding Mould: Wooden Cases for Vertical/Horizontal Rotational Molding

Rotomoulding Mould is the perfect choice for customizing rotational molding with wooden cases for vertical and horizontal applications. The process begins with the use of CNC machining to achieve the desired dimensions and shape, followed by the application of the rotomoulding technique to create a high-quality mold. The wooden cases provide excellent protection for the mold, ensuring its longevity and stability in the rotational molding process. The custom design of the mold can be tailored to the exact specifications of the desired product, and the end result is a perfectly shaped and durable product.

Rotomoulding Mould is an ideal solution for both commercial and industrial use, due to its robustness and reliability. It is highly resistant to wear and tear, and the wooden cases provide excellent protection against environmental factors such as water and humidity. The rotational molding process enables the production of complex shapes and intricate details, making it suitable for a wide range of products and applications. With the use of CNC machining, the mold can be precisely tailored to the customer’s exact specifications, allowing for a perfect fit and top-quality end product.

Rotomoulding Mould is the perfect choice for any application requiring the use of rotational molding. The wooden cases provide excellent protection for the mold during the rotational molding process, while the CNC machining ensures a precise fit and top-quality product. The custom design of the mold can be tailored specifically for the desired product, and the end result is a perfectly shaped and durable product.

Customization:

Custom Rotomoulding Mould

We offer custom rotomoulding moulds with a variety of features to meet your specific requirements. Our custom rotomoulding moulds are available in silver, with a smooth surface and can be customized to the desired weight. Choose from either vertical or horizontal shapes and they are processed via CNC machining.

Support and Services:

Rotomoulding Mould Technical Support and Service

We provide technical support and service for our Rotomoulding Mould products. Our experienced team of experts are available to answer any questions you may have and help you with your project.

We offer the following services:

- Installation and maintenance of the moulds

- Inspection and testing of the moulds

- Repair and replacement of mould parts

- Advice on the selection of mould materials and processes

- Troubleshooting and problem-solving

- Optimization of the mould design and processes

We are committed to providing the highest quality technical support and service for our Rotomoulding Mould products. If you have any questions or would like more information, please don't hesitate to contact us.

Packing and Shipping:

Rotomoulding Mould is packaged and shipped with the following guidelines in mind:

- The moulds should be thoroughly cleaned before packing.

- The moulds should be wrapped in a waterproof material.

- The moulds should be placed in a secure box to ensure that no damage occurs during transport.

- The box should be labeled with the name of the mould and the destination.

- The box should be secured with appropriate packing materials.

- The moulds should be shipped in a timely manner to ensure they reach their destination safely.

FAQ:

- Q1: What is Rotomoulding Mould?

- A1: Rotomoulding Mould is a moulding process used to produce hollow plastic products, such as tanks, containers, large toys and other objects with complex shapes.

- Q2: What is the advantage of Rotomoulding Mould?

- A2: The advantage of Rotomoulding Mould is that it can produce hollow plastic products with complex shapes and thicknesses that cannot be achieved with other traditional moulding processes.

- Q3: What materials can be used with Rotomoulding Mould?

- A3: Rotomoulding Mould can be used with a variety of materials, such as polyethylene, polypropylene, polyvinyl chloride, polyurethane, and polycarbonate.

- Q4: What is the process of Rotomoulding Mould?

- A4: The process of Rotomoulding Mould involves heating a powdered or granular plastic material until it is soft and then placing it into a mould. The mould is then rotated in two directions to ensure even thickness and that all of the features of the product are achieved.

- Q5: What products can be produced with Rotomoulding Mould?

- A5: Rotomoulding Mould can be used to produce a variety of products, such as tanks, containers, large toys, and other hollow plastic products with complex shapes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!